Prefabricated Steel Building Structure

Things to Know About Prefabricated Houses

Prefabricated steel buildings with many outstanding advantages are currently widely used in the construction industry. Many businesses and investors choose prefabricated houses because it saves costs, shortens construction time, reduces foundation structure but still ensures incredible bearing capacity. So Prefabricated steel building structure What's so special about them being able to do that? Find out now.

What is a Pre-Engineered Steel Building?

Prefabricated steel buildings are a type of house made up of mainly steel components. They are installed according to architectural drawings in a short time. Steel buildings require extremely strict technical standards to ensure safety and load-bearing capacity.

Today, with its flexibility, low cost and quick construction time, pre-engineered steel buildings are widely used in manufacturing and warehouse projects. In addition, civil pre-engineered steel buildings today are also becoming more and more popular in big cities, typically in projects of restaurants, cafes, supermarkets, showrooms,...

Advantages of Prefabricated Steel Buildings

Some outstanding advantages of pre-engineered steel buildings compared to other types of houses include:

- Installation and construction are simple and quick, not affected by weather too much like traditional methods.

- Flexibility in installation helps make the most of space.

- Easily expand the scale and relocate the project to another location.

- Significant savings in costs and time because the components are pre-fabricated.

- Relatively long lifespan, good bearing capacity.

- Light weight compared to other materials helps apply pressure to the foundation.

Basic Parameters of Prefabricated Houses

Prefabricated steel frame technology was introduced to the market, it has become an effective alternative to old warehouse and factory construction options. In addition, it is also used in offices, restaurants, etc. It is convenient, but you also need to check some of the following specific technical specifications to ensure safety.

- Aperture: horizontal distance of the house.

- Column step: distance between 2 columns calculated vertically. This distance is usually from 6m to 12m long

- House height: This is the height of the boundary columns, which determines the ventilation of the house and workshop.

- Roof slope: usually ranges from 10 to 30 degrees to ensure convenient drainage of rainwater.

- Base load: Depends on function and usage needs to decide accordingly.

- Roof load: Consider the load of corrugated iron roofs, insulation panels, technical systems, ceiling management, etc.

It is necessary to calculate the above parameters in detail and scientifically Prefabricated steel building structure be stable and safe.

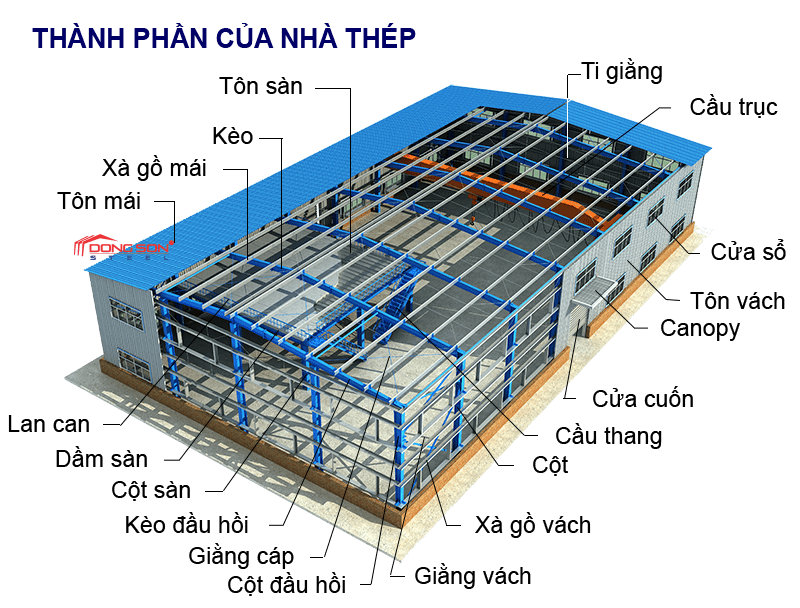

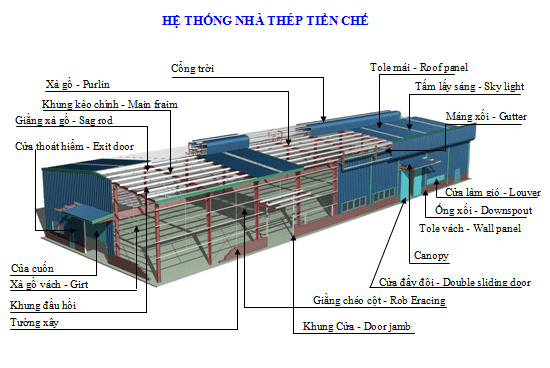

Prefabricated Steel Building Structure

Prefabricated steel building structure divided into 6 main parts. Find out details with us right below.

Foundation structure

Prefabricated steel buildings still use reinforced concrete foundation structures. Surely everyone knows the importance of building a solid foundation for a house; For prefabricated houses, the foundation is equally necessary. The foundation has the effect of supporting the entire load of the house and factory. There are many types of foundation structures, depending on the needs and tonnage of the project.

Installing and building foundations for prefabricated houses is an extremely important step and requires high precision. Prefabricated steel building structure Whether it is stable or not depends a lot on this step.

Prefabricated House Background

The floor will usually be poured concrete. The thickness of this concrete layer will depend on the investor's intended use.

Main Frame System: Columns, Beams, Trusses

Steel columns, beams and trusses are the three main components Prefabricated steel building structure. They are designed by architects to ensure they have enough load-bearing capacity and are durable over time.

Steel columns and trusses are often designed in an H shape, they will be linked together with gusset plates and high strength bolts.

Sky Door And Canopy Roof

The skylight will provide ventilation to help keep the factory airy during use. Canopy is a lobby roof system that provides sun and rain protection at the main door and window location.

Purlins and Bracing System

The system of purlins, roof braces, and column braces, although not large in volume, is an indispensable part Prefabricated steel building structure. This system has the effect of increasing the stability and rigidity of the main structural frame system. There have been many cases of factories being deformed because of subjective failure to install this system.

Ton Bao Che

Using a color-plated corrugated iron helps increase aesthetics while avoiding environmental corrosion. In addition, you should also use an insulation layer made of glass wool or airbags to prevent heat and noise in the factory.

Conclude

Above is all the information about the advantages and disadvantages Prefabricated steel building structure. Hopefully it will be useful for you to choose the most effective, convenient and economical construction plan.

Dong Son Mechanical and Construction Company Limited

- Lot B310-311-312 Vinatex Tan Tao Industrial Park, Hiep Phuoc Town, Nhon Trach District, Dong Nai Province

- Phone: (251) 3569192

- Mobile: 098 513 4499

Ho Chi Minh City Transaction Office

- No. 186, Street 1, Tan Phu Ward, District 7, City. Ho Chi Minh

- Phone: (028) 6261 4499

- Email : info@dongsonsteel.com.vn

- FB: https://www.facebook.com/dongsonsteel.com.vn